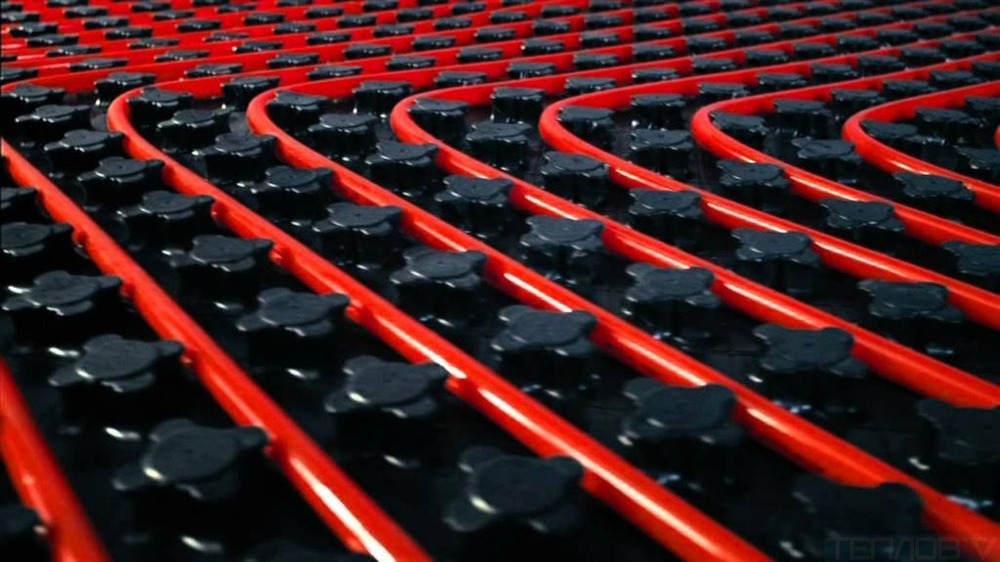

Underfloor heating foam

Kardo foam is produced with fully automatic machines using (EPS) materials in the shape of an egg comb. This product is suitable for implementing floor heating systems in residential, commercial, office, industrial, sports, cultural, etc. buildings. Its use saves energy, increases the comfort and health of residents, reduces maintenance and repair costs, increases the useful life of the building, and improves its beauty and appearance.

Laminated eggshell foam

Laminated eggshell foam, due to its special material and Heimpack coating, directs heat upwards and prevents energy loss. This feature increases energy efficiency in the interior space. It should be noted that the coating density varies between 100 and 220 microns, depending on the customer's request and order.

- Regular holes for heating pipes

- Moisture-proof layer to prevent water penetration

- Sound-proof layer to reduce sound transmission

- Anti-slip layer to prevent floor movement

- Fireproof layer for heat resistance

- Locked edges to prevent shifting

Coated foam specifications:

- Ease of foam and piping installation for underfloor heating

- No need for measurements by facility managers

- High speed of implementing the underfloor heating system

- Slow-burning nature of foam raw materials

- No Concrete moisture absorption

- High resistance to crushing and breaking when walking on foams during plumbing

- Easy storage

- Easy implementation of underfloor heating system in swimming pool walls

- Designing underfloor heating map based on raft-to-radar sizes Foams